Introduction Of Forum Energy Technologies WPCE Sizes

Forum Energy Technologies (FET) is a global leader in providing high-quality products and services for the energy sector. Among their many offerings, Well Pressure Control Equipment (WPCE) is essential for ensuring the safety and efficiency of oil and gas operations. WPCE sizes play a critical role in these operations, determining how well the equipment will perform under varying pressure conditions.

What is WPCE?

Well Pressure Control Equipment (WPCE) refers to the systems and components used to manage and control the pressure within a well during drilling and production. WPCE is vital for maintaining safety and operational efficiency in the oil and gas industry. The equipment typically includes blowout preventers (BOPs), chokes, kill lines, and other pressure control devices that work together to prevent blowouts and other pressure-related incidents.

The primary purpose of WPCE is to regulate and stabilize well pressure, ensuring that it remains within safe limits. This is crucial for protecting both the workforce and the environment from the dangers associated with uncontrolled pressure surges. Properly sized WPCE is essential for the equipment to function effectively, as the wrong size can lead to inadequate pressure control, increasing the risk of accidents.

Understanding WPCE Sizes

Why Size Matters in WPCE

Forum Energy Technologies WPCE sizes are a critical factor in the overall effectiveness of pressure control operations. The size of the equipment must align with the specific needs of the well, including the expected pressure levels, well depth, and the type of fluids being managed. A mismatch in forum energy technologies WPCE sizes can lead to inefficiencies, increased wear and tear on equipment, and, in worst-case scenarios, catastrophic failures like blowouts.

WPCE sizing is not a one-size-fits-all approach; it requires careful consideration of the operational environment. For example, a well with high-pressure zones will require WPCE that can withstand those pressures without compromising performance. Conversely, using oversized equipment for a lower-pressure well can be unnecessarily costly and cumbersome.

Common WPCE Sizes in the Industry

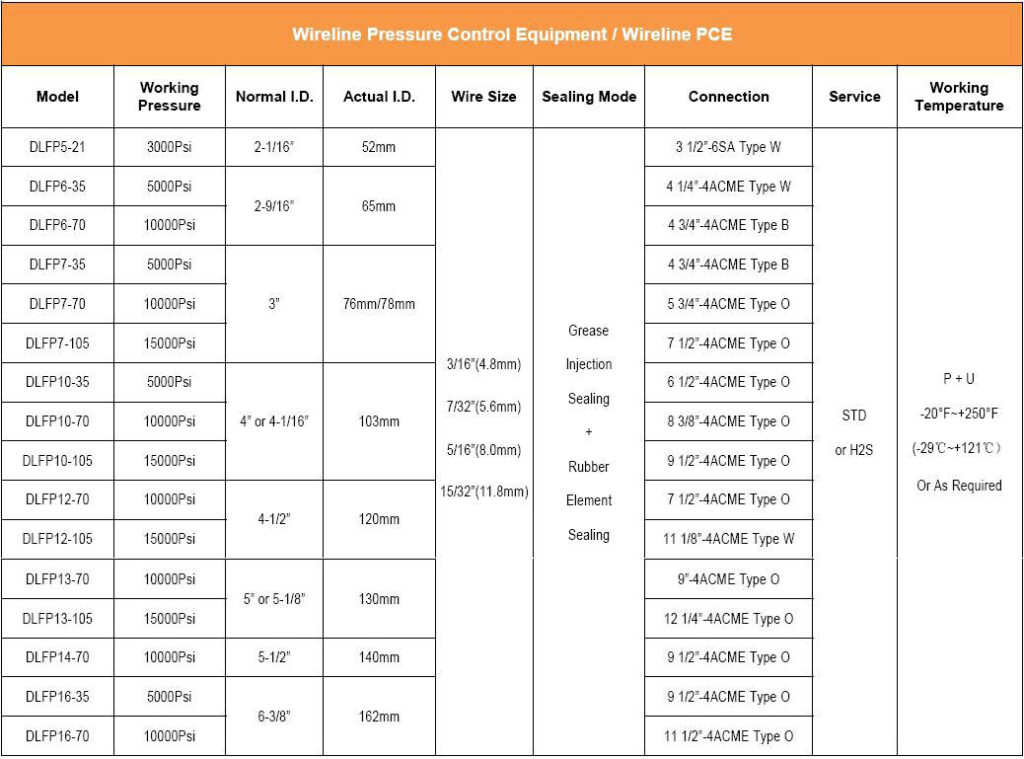

In the oil and gas industry, Forum Energy Technologies WPCE sizes are typically standardized to ensure compatibility and ease of replacement across different operations. Common WPCE sizes include:

- Blowout Preventers (BOPs): These are available in various sizes, typically ranging from 7 1/16″ to 21 1/4″ in diameter. The size selected depends on the casing size and the expected pressure.

- Choke Manifolds: These are designed with different choke sizes, often in the range of 2″ to 5″, depending on the flow rate and pressure requirements.

- Kill Lines: The size of kill lines can vary, but they generally range from 2″ to 4″ in diameter, designed to handle specific kill fluid volumes and pressures.

Understanding these standard sizes and how they apply to different well conditions is crucial for selecting the appropriate WPCE for any given operation.

Forum Energy Technologies’ Approach to WPCE Sizes

Customization Options

Forum Energy Technologies WPCE sizes recognizes that every well is unique, and so are its pressure control needs. To address this, FET offers a range of customizable WPCE sizes. Clients can work with FET engineers to design WPCE systems tailored to their specific requirements, ensuring optimal performance and safety.

Customization options include adjusting the dimensions of BOPs, modifying choke sizes to match specific flow rates, and selecting kill line diameters that are best suited for the type of fluids and pressures encountered in the well. This flexibility allows operators to optimize their pressure control strategies, reducing the risk of equipment failure and enhancing operational efficiency.

Standard WPCE Sizes Offered

While customization is a key offering, Forum Energy Technologies also provides a comprehensive range of standard WPCE sizes that meet the needs of most operations. Forum Energy Technologies WPCE sizes have been developed based on extensive industry experience and are designed to provide reliable performance across a wide range of conditions.

The standard sizes are categorized based on equipment type, with each category offering several size options to suit different well specifications. Whether an operator needs a compact BOP for a shallow well or a robust choke manifold for high-pressure drilling, FET’s standard WPCE sizes deliver dependable results.

Selecting the Right Forum Energy Technologies WPCE Sizes

Factors to Consider in Forum Energy Technologies WPCE Sizes

Selecting the right WPCE size involves considering several critical factors, including:

- Well Pressure: The maximum expected pressure in the well dictates the strength and size of the WPCE.

- Casing Size: The size of the wellbore and casing directly influences the selection of WPCE, particularly BOPs.

- Flow Rate: The anticipated flow of drilling fluids or production fluids determines the appropriate size for chokes and kill lines.

- Type of Fluid: Different fluids exert varying levels of pressure and require specific WPCE materials and sizes to handle them safely.

Each of these factors must be carefully evaluated to ensure that the selected WPCE size provides the necessary protection and operational efficiency.

Matching WPCE Size to Project Requirements

To match the WPCE size to specific project requirements, operators should collaborate with equipment suppliers like Forum Energy Technologies WPCE sizes to conduct detailed assessments of well conditions. This includes pressure modeling, flow simulations, and material compatibility studies. By aligning the WPCE size with the precise demands of the well, operators can achieve greater control over well pressures, minimize risks, and optimize overall project outcomes.

Benefits of Proper Forum Energy Technologies WPCE Sizing

Efficiency and Safety in Operations

Proper Forum Energy Technologies WPCE sizes are integral to maintaining the safety and efficiency of drilling and production operations. Correctly sized equipment ensures that pressure is controlled effectively, preventing dangerous pressure surges that could lead to blowouts or other catastrophic failures.

In addition to enhancing safety, well-sized WPCE contributes to the overall efficiency of the operation. Equipment that matches the well’s requirements operates more smoothly, reduces downtime, and minimizes maintenance costs.

Cost-Effectiveness of Correct Sizing

While it might seem tempting to opt for smaller, less expensive WPCE, doing so can lead to costly consequences. Inadequately sized equipment often fails to perform under high-pressure conditions, leading to frequent breakdowns, costly repairs, and potentially dangerous situations.

On the other hand, investing in properly sized WPCE from the outset can save operators significant money in the long run by reducing maintenance costs, preventing equipment failure, and avoiding costly operational disruptions. The right size WPCE ensures a balance between upfront investment and long-term operational efficiency.

Innovations in WPCE Technology by Forum Energy Technologies

Advancements in Forum Energy Technologies WPCE Sizes Design

Forum Energy Technologies WPCE sizes has been at the forefront of innovations in Well Pressure Control Equipment (WPCE), continuously improving the design and functionality of its products. One key area of advancement is the integration of advanced materials and technologies that enhance the durability and efficiency of WPCE.

For example, FET has developed WPCE with improved resistance to corrosion and wear, which is especially critical in harsh drilling environments. These innovations extend the lifespan of the equipment and reduce the need for frequent replacements, leading to cost savings for operators.

Additionally, FET has introduced smart WPCE systems that incorporate sensors and real-time monitoring capabilities. These systems allow operators to track the performance of the equipment and make adjustments as needed to maintain optimal pressure control. The ability to monitor WPCE performance in real-time enhances safety and efficiency by allowing for quick responses to any pressure anomalies.

Future Trends in Forum Energy Technologies WPCE Sizes

The future of Forum Energy Technologies WPCE sizes is likely to be shaped by the increasing demand for automation and digitalization in the oil and gas industry. Forum Energy Technologies is already exploring these trends by developing WPCE that can be integrated into automated drilling systems. This integration will allow for more precise control of well pressures, reducing human error and improving overall operational safety.

Another emerging trend is the development of more environmentally friendly WPCE. As the industry shifts towards more sustainable practices, FET is focusing on creating WPCE that minimizes environmental impact, such as reducing emissions and waste during drilling operations.

Case Studies: WPCE Success Stories with Forum Energy Technologies

Case Study 1: High-Pressure Well in the North Sea

In one of the most challenging drilling environments in the North Sea, Forum Energy Technologies WPCE sizes provided customized WPCE solutions to manage extremely high well pressures. The project required equipment that could withstand pressures exceeding 15,000 psi, while also maintaining reliable performance in a cold and corrosive environment.

FET supplied a range of WPCE, including custom-designed BOPs and choke manifolds, specifically tailored to the project’s requirements. The result was a successful drilling operation with no pressure-related incidents, demonstrating the effectiveness of FET’s WPCE in extreme conditions.

Case Study 2: Deepwater Drilling in the Gulf of Mexico

In the Gulf of Mexico, Forum Energy Technologies WPCE sizes played a crucial role in a deepwater drilling project that required advanced WPCE to handle unpredictable well pressures. The project’s complexity was compounded by the depth of the well and the challenging underwater conditions.

FET provided a comprehensive WPCE solution that included advanced BOPs and real-time pressure monitoring systems. These innovations allowed the drilling team to maintain precise control over well pressures, preventing blowouts and ensuring the safety of the operation. The project was completed ahead of schedule, highlighting the reliability and efficiency of FET’s WPCE.

Conclusion and Key Takeaways

Recap of Main Points of Forum Energy Technologies WPCE Sizes

Throughout this article, we’ve explored the critical role of Well Pressure Control Equipment (WPCE) in the oil and gas industry. We’ve discussed how WPCE sizes are vital to ensuring operational safety and efficiency, the importance of selecting the right WPCE size for specific well conditions, and how Forum Energy Technologies offers both standard and customized WPCE solutions.

We’ve also highlighted the innovations FET has brought to the industry, including advancements in WPCE design and the integration of smart technologies for real-time monitoring. Case studies further illustrate how FET’s WPCE has been instrumental in successful drilling operations in some of the most challenging environments.

Final Thoughts on Forum Energy Technologies WPCE Sizes

Selecting the right WPCE and working with a reliable partner like Forum Energy Technologies WPCE sizes is crucial for the success of any drilling operation. FET’s commitment to innovation and customization ensures that operators can find the right equipment for their specific needs, leading to safer, more efficient, and cost-effective operations. As the industry continues to evolve, FET’s focus on technological advancements will undoubtedly keep them at the forefront of WPCE solutions.

Frequently Asked Questions (FAQs)

-

What is Well Pressure Control Equipment (WPCE)?

- WPCE refers to the equipment used in oil and gas drilling to manage and control well pressures. This includes devices like blowout preventers (BOPs), choke manifolds, and kill lines.

-

Why is the size of WPCE important?

- The size of WPCE is critical because it must match the specific well conditions, including pressure levels, well depth, and fluid types. Incorrect sizing can lead to equipment failure or safety hazards.

-

Can WPCE be customized for specific well conditions?

- Yes, Forum Energy Technologies offers customizable WPCE options tailored to meet the specific requirements of different well conditions, ensuring optimal performance and safety.

-

What innovations has Forum Energy Technologies WPCE Sizes introduced in WPCE?

- FET has introduced innovations such as corrosion-resistant materials, smart WPCE systems with real-time monitoring capabilities, and environmentally friendly designs.

-

How does WPCE contribute to drilling safety?

- WPCE plays a crucial role in maintaining well pressure control, preventing blowouts, and ensuring the safety of the drilling operation. Properly sized and maintained WPCE is essential for safe drilling.